- UP’s 24 Hours in Hotel

- Inspired by the Tesla Gigafactory

- The Product Design Concept of Yunji

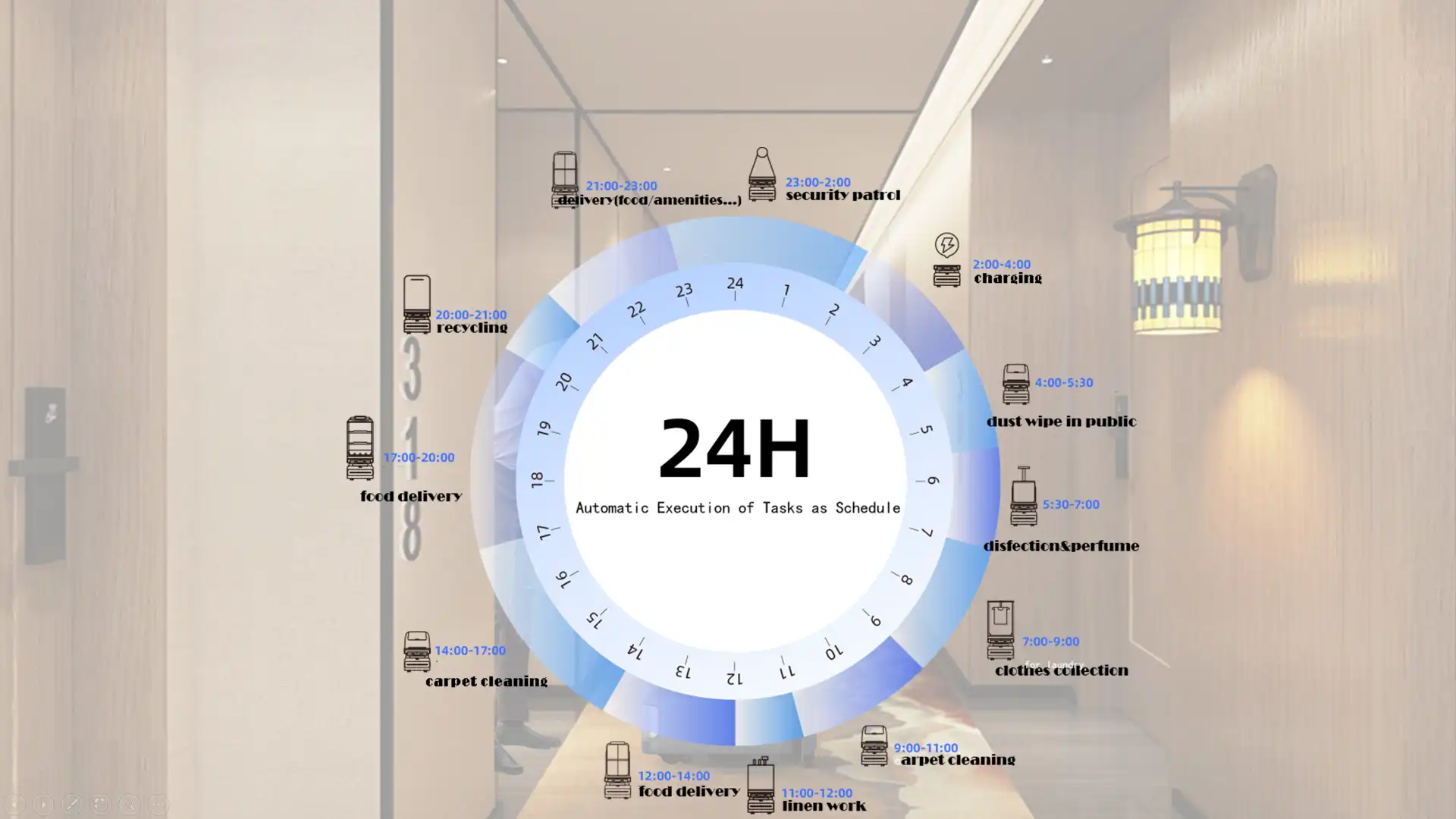

UP‘s 24 hours in hotel

At 8 o’clock in the morning, UP sent warmth to Ms. Zhang, and at 11 o’clock, the work order system promoted the collaboration between man and UP. At 3 o’clock in the afternoon, UP carried out carpet cleaning and garbage collection, and at 6 o’clock in the evening, UP delivered food, and also sung one birthday song to the resident. At ten o’clock in the evening, UP delivered a bowl of hot dry noodles to the traveler. At three o’clock in the morning, UP began to clean the lobby. It was a busy day for UP. Keeping UP busy is the basis of our product design.

Inspired by the Tesla Gigafactory

What exactly is the first principle of our product design? We certainly don’t iterate for the sake of iterating, nor can we upgrade for the sake of upgrading. We went to visit Tesla’s factory, and were shocked by Tesla’s Gigafactory in Lingang, China. The factory no longer has a warehouse, there is no line warehouse, all the trucks that come are its warehouses. It has more than 300 slots, and all the trucks come and deliver the goods directly to the production line.

We were thinking, why was Musk able to do this? Why did he make a factory that was different from others? How much more has he been more efficient? In fact, Musk is good at thinking from first principle when solving problems, but this problem is not easy to solve, we can’t patch and add functions every day, but to think about what customers want and how we should make the best design.

The product design concept of Yunji

The product design and product iteration of Yunji are generally done from five aspects: function, performance, availability, ease of use and cost.

Functionally, what users actually want is an extremely cost-effective product, a product that matches price and value. The most expensive part of the up robot is the motion sensor navigation system, and we abstract the most expensive part into an up platform. In this way, the cost of all robot modules can be well controlled.

Based on our understanding of the upstream supply chain and the technology path, we iterated on many key factors, such as three electricity. Our battery life has increased by 30%, the number of battery charging and discharging times has tripled, and there are BMS chips and temperature control chips, which can make our robots safer. Our motor torque needs to be greater, because the robot not only needs to deliver goods, but also vacuum, and there are many other scenarios. We have more sensors on robot, some upward, forward, backward, and both sides, and the closed loop of sensors can make the robot walk more steadily and accurately in the environment. As the data from the sensors increases, it required iterative computing power, which is about three times that of the previous one. The data allowed us to do a deep iteration of our algorithm.

Then, for the pursuit of quality, we have done more than normal level or excessive testing of each component. For products, we think about the production line as part of the product, which allows us to have more possibilities to reduce costs in the future.